The basic principle of the special energy household waste pyrolysis gasification power generation system is to convert household waste and other waste into combustible gas through a gasification furnace after pre-treatment, and then use combustible gas as fuel for gas boilers. After producing steam, the steam drives the steam turbine to work and generate electricity. It can solve the increasingly serious problem of ineffective harmless and reduced treatment of urban household waste, making it one of the more effective and clean utilization methods for waste treatment.

Stage 1 Garbage Pretreatment

The main equipment for garbage pretreatment includes conveyor belts, sorting equipment, etc. The entire process flow is as follows: the garbage is manually removed from some large objects (further crushed for pyrolysis and gasification), recyclable items, harmful substances, etc; After being sorted by a drum screen equipment, combustible materials (paper products, wood products, garden pruning branches, textiles, harmless plastics, etc.) that can be used for pyrolysis and gasification are obtained. Organic waste can be used for biogas or composting treatment, while recyclable waste such as metal and glass can be recycled for treatment.

Two-stage gasification power generation

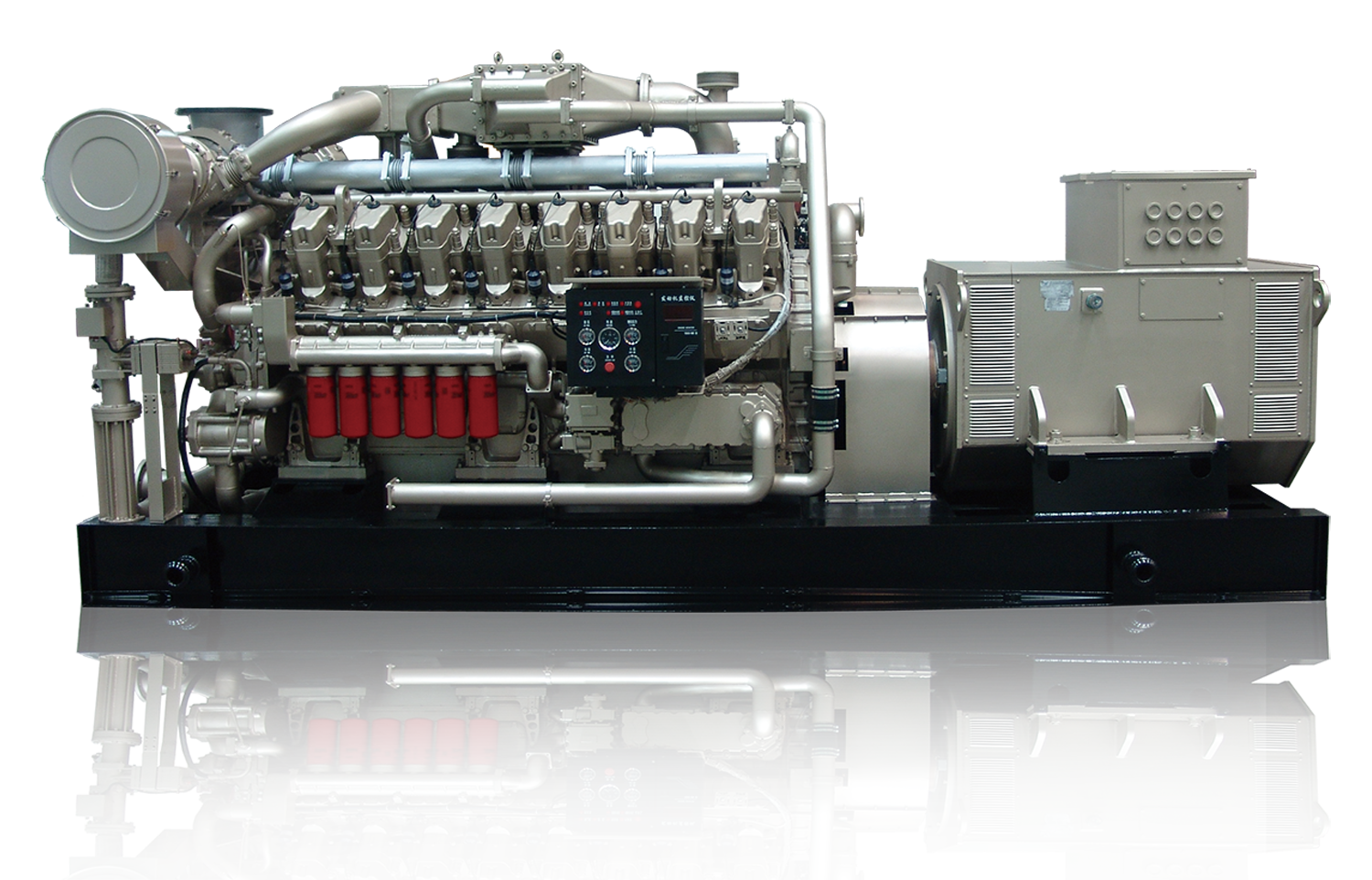

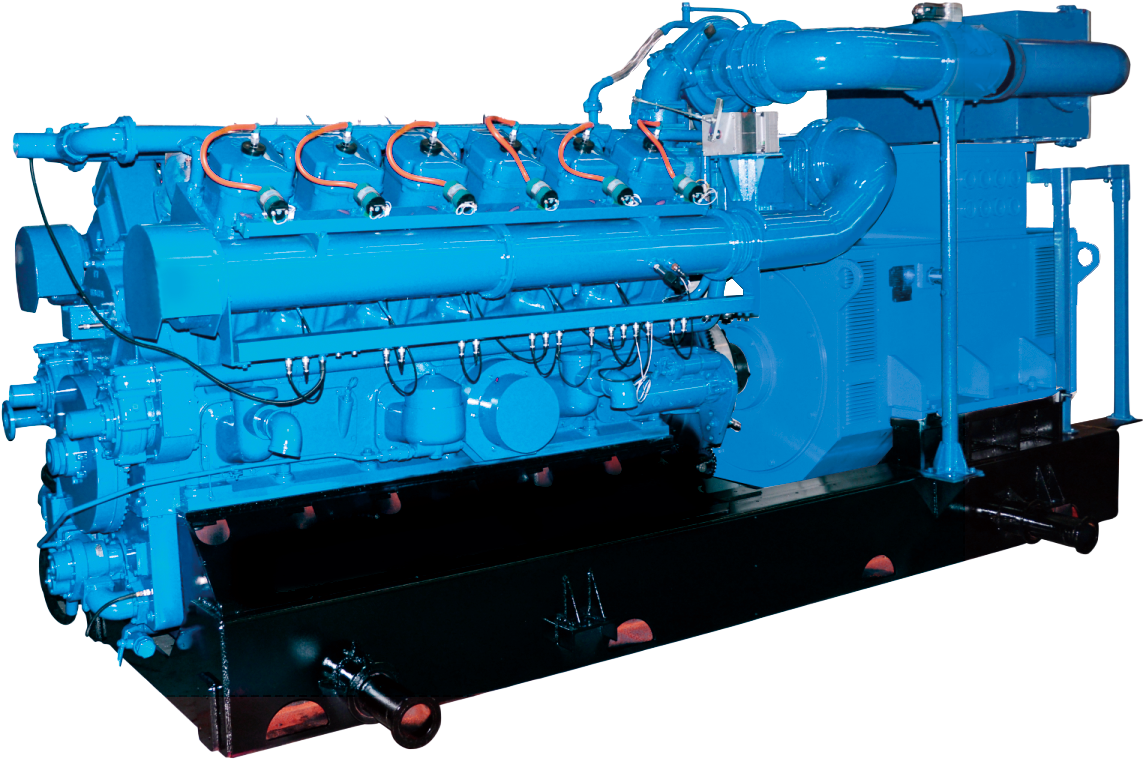

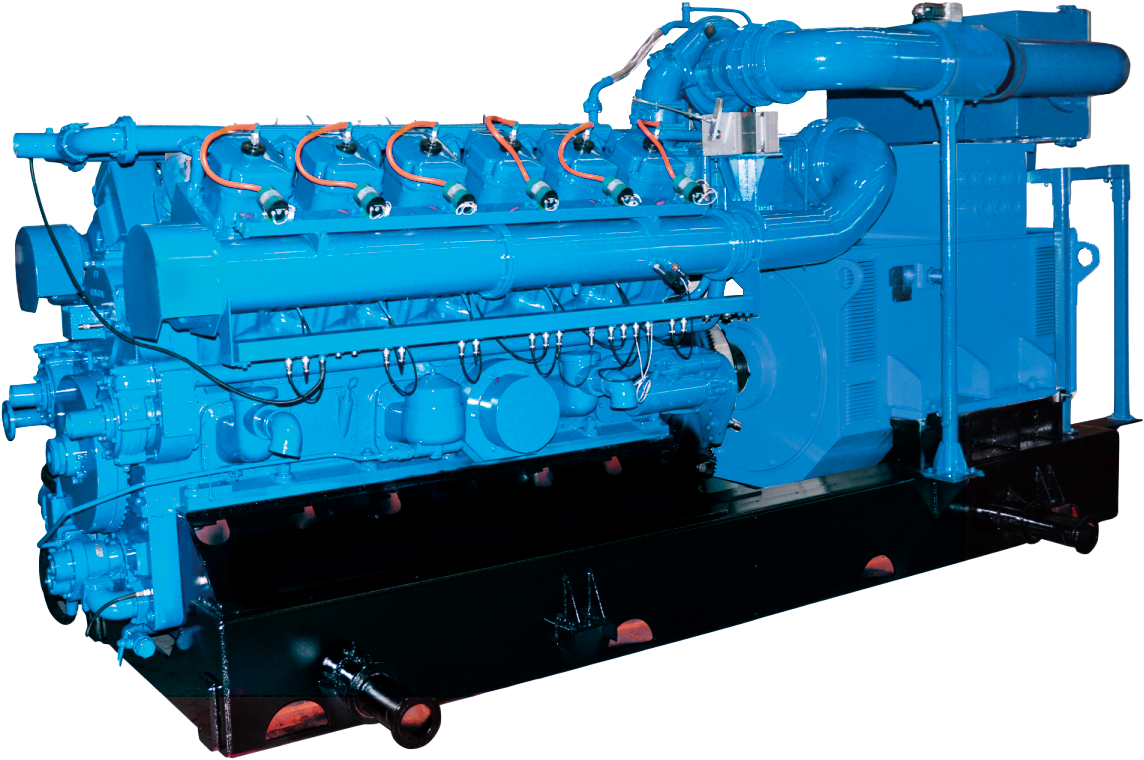

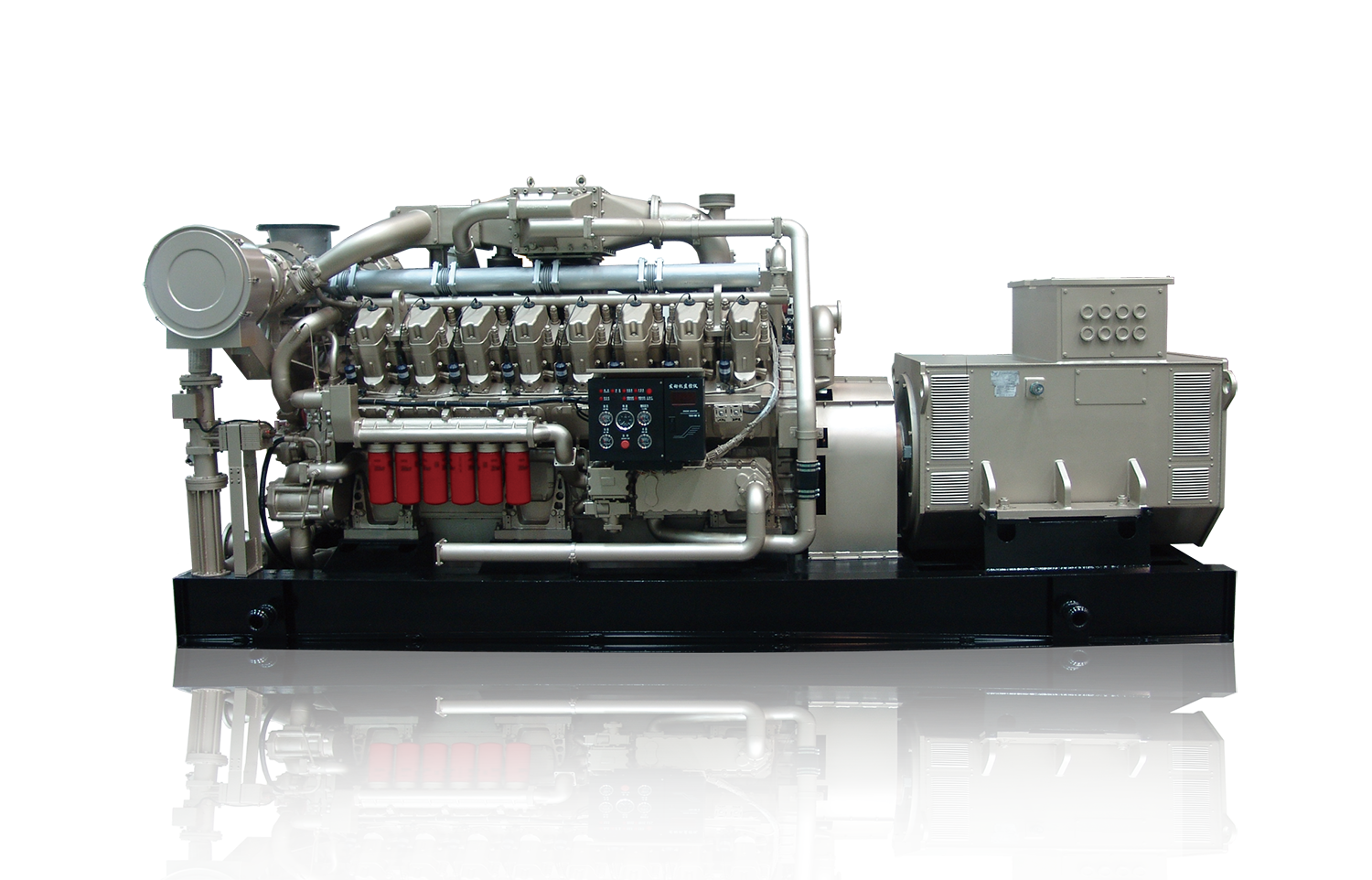

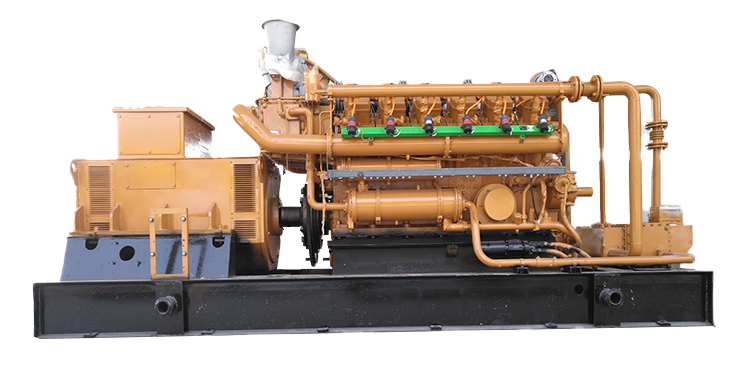

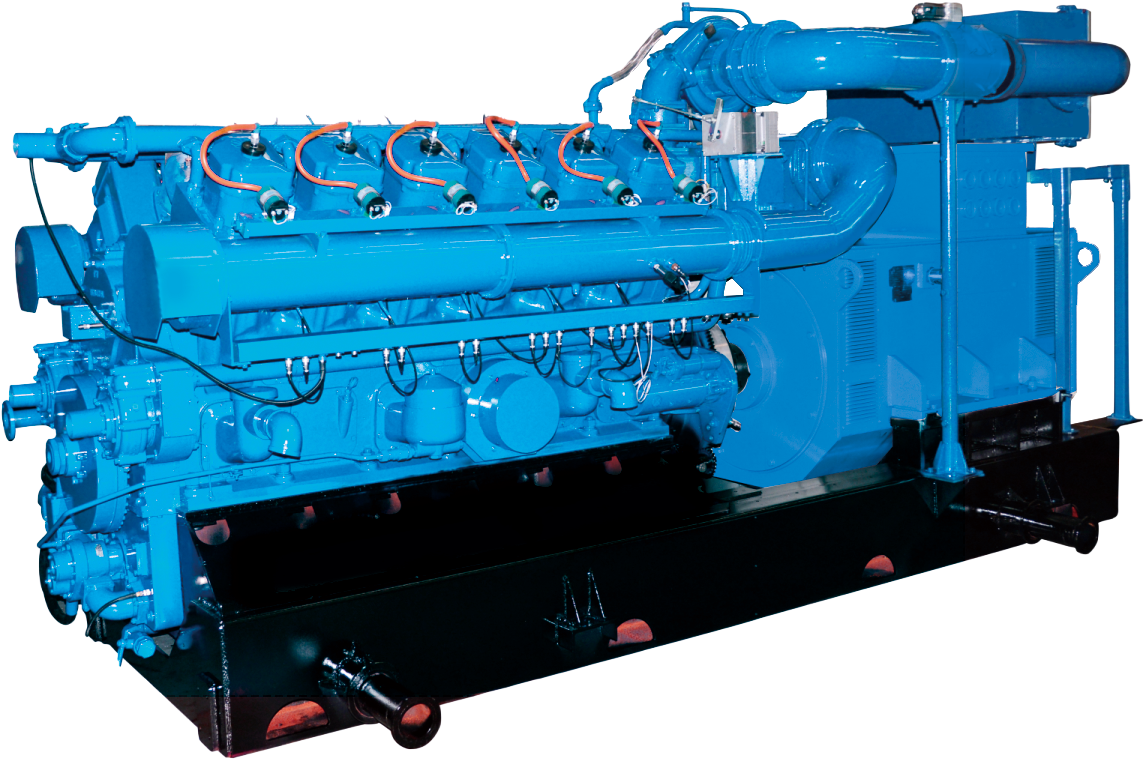

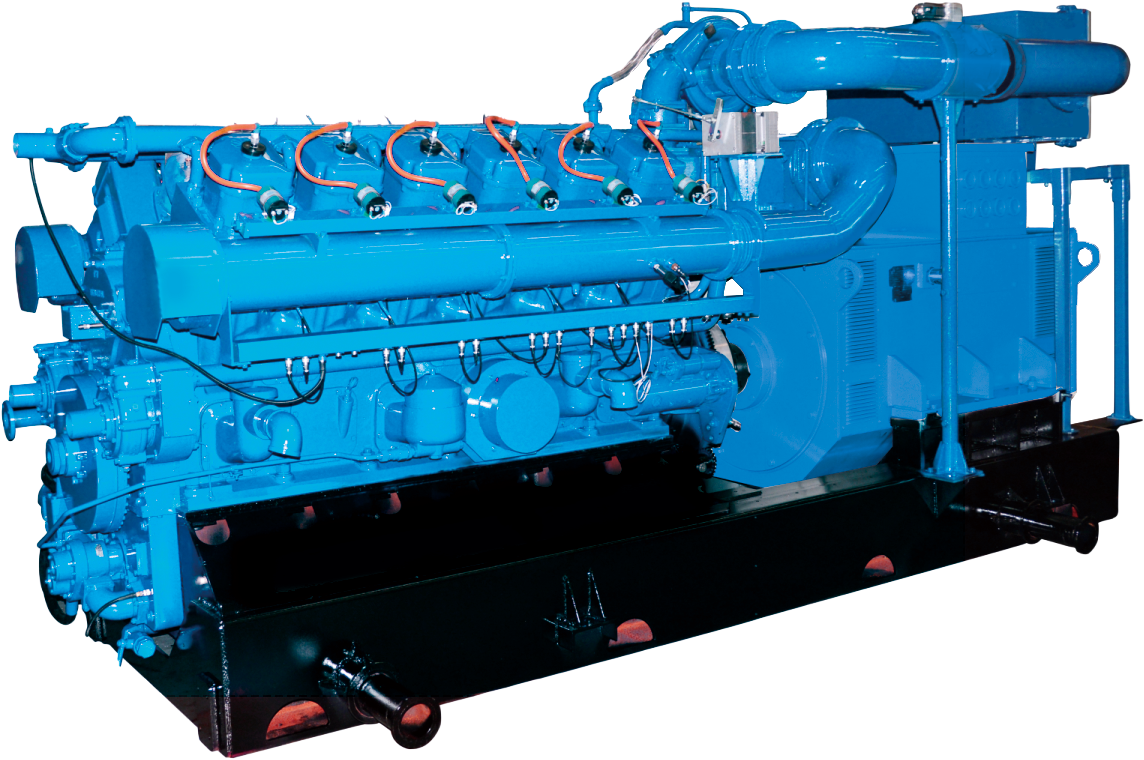

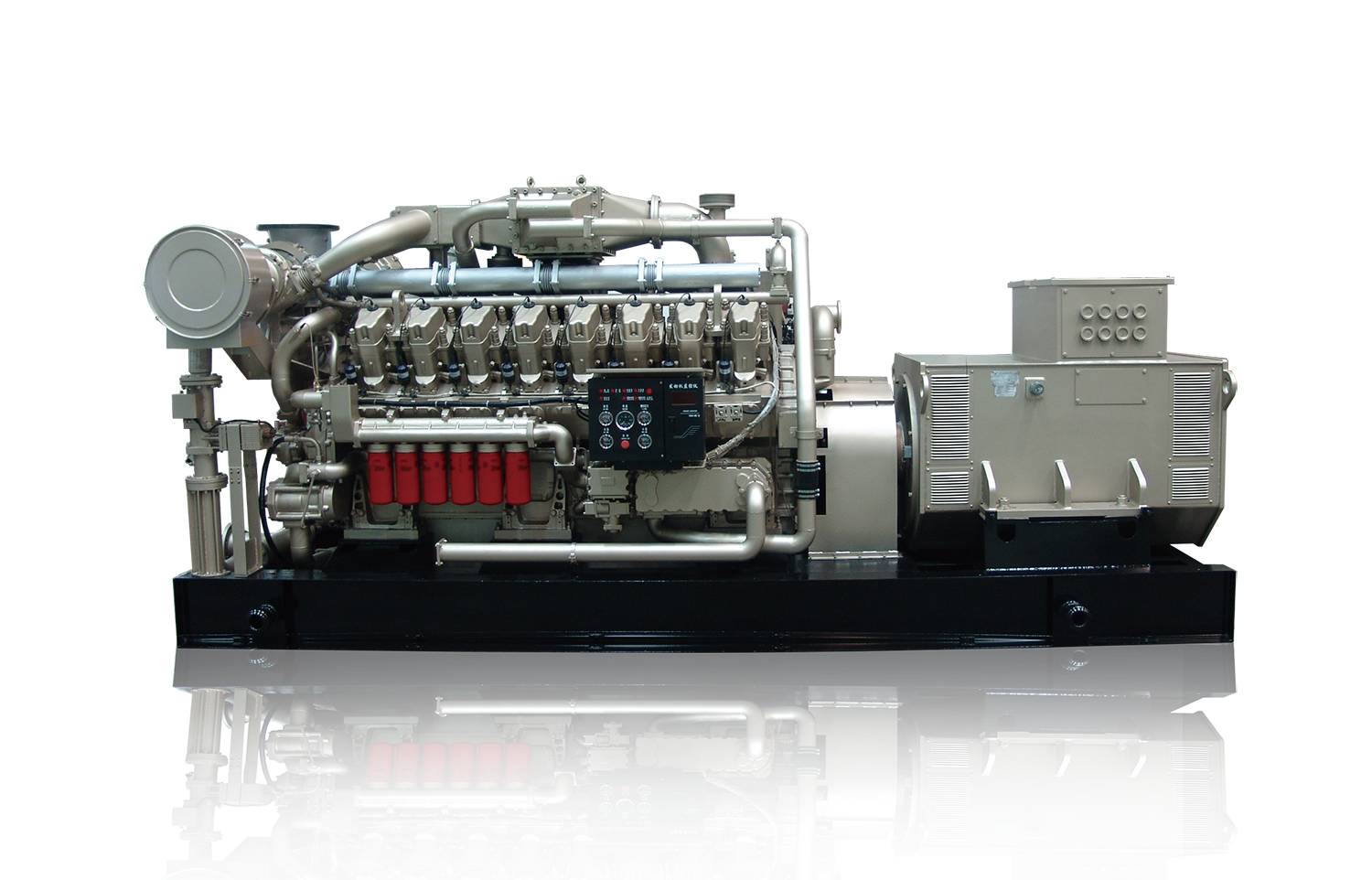

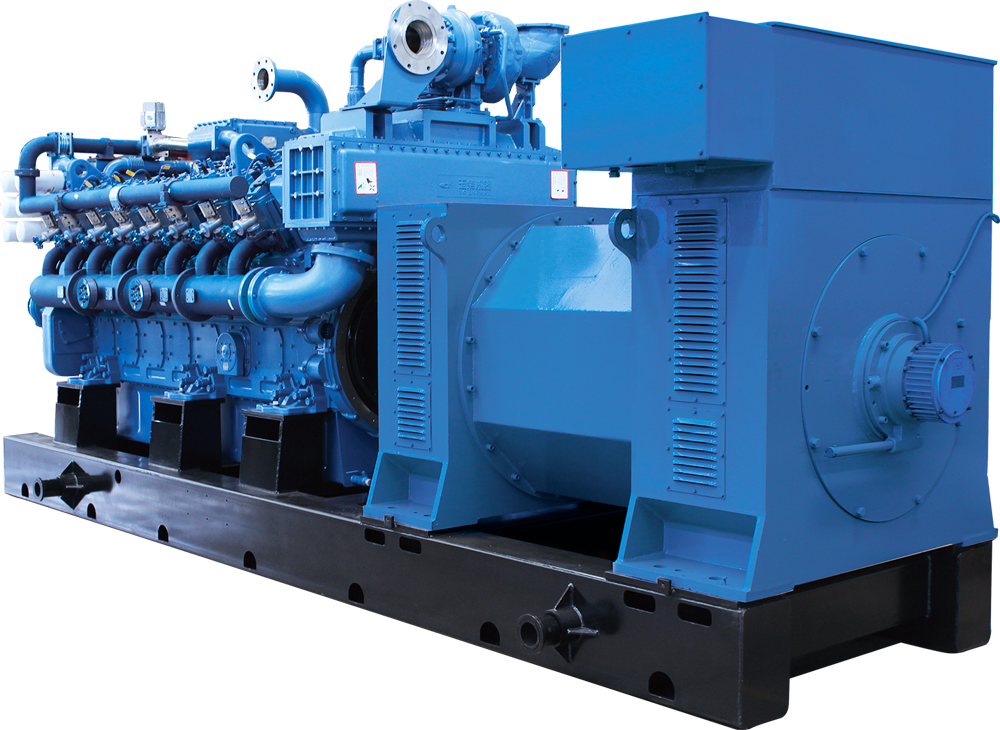

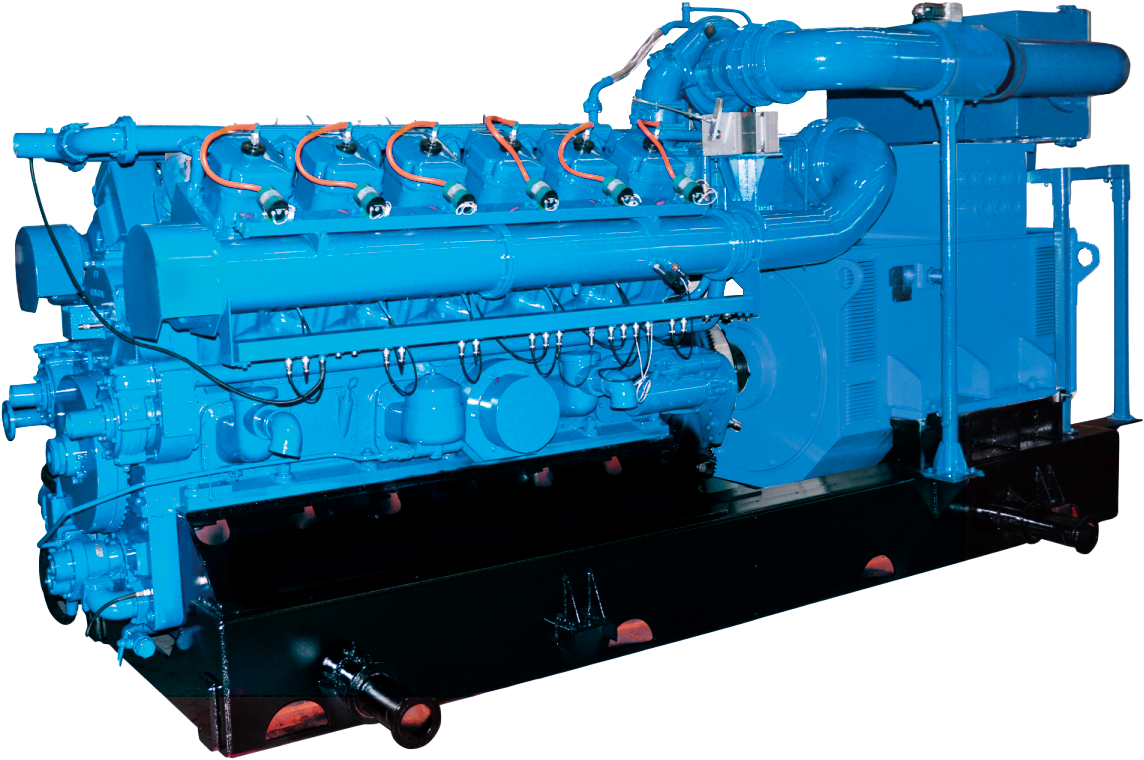

The main equipment of the gasification power generation system includes: feeding and feeding equipment, gasification furnace, gas boiler, steam turbine, flue gas treatment system, etc. The entire process is basically divided into: the pre-treated waste enters the gasification furnace for pyrolysis and gasification, and the solid fuel is converted into combustible gas; Combustible gas is used as fuel for gas boilers to produce steam; Steam drives the stable operation of the steam turbine to output electrical energy; The boiler flue gas is discharged after purification.

This article is provided by the straw gas generator set for assistance. For more related content, please click on I hope this article can be helpful to you. Thank you for reading!

Tel:0531-69953988

Tel:0531-69953988  Add:101, Building 5, Liandong U Valley Science and Technology Innovation Center, Zhangjin Comprehensive Bonded Zone, No. 33688 Jingshi East Road, Suncun Street, Jinan Area, China (Shandong) Pilot Free Trade Zone

Add:101, Building 5, Liandong U Valley Science and Technology Innovation Center, Zhangjin Comprehensive Bonded Zone, No. 33688 Jingshi East Road, Suncun Street, Jinan Area, China (Shandong) Pilot Free Trade Zone