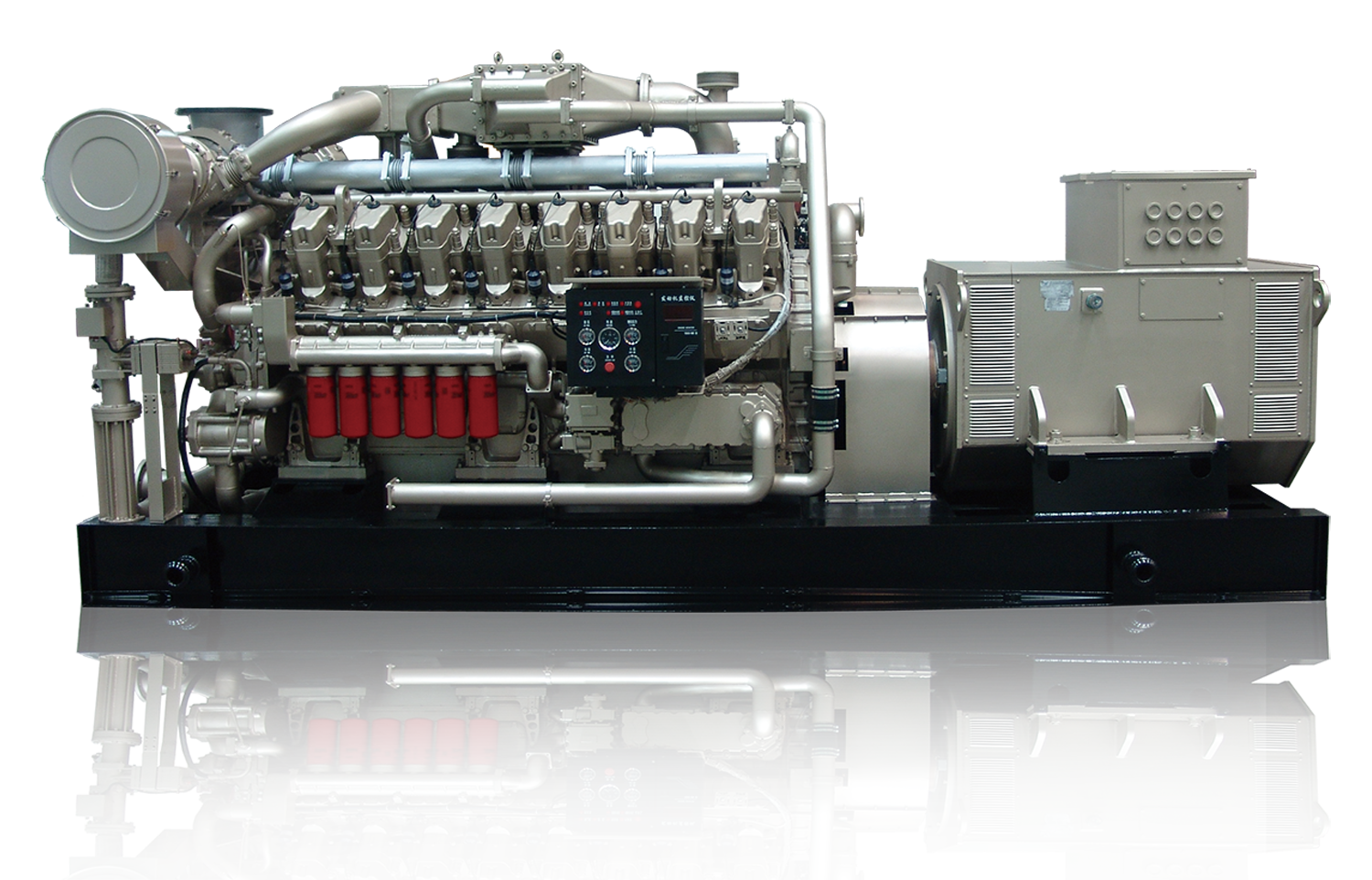

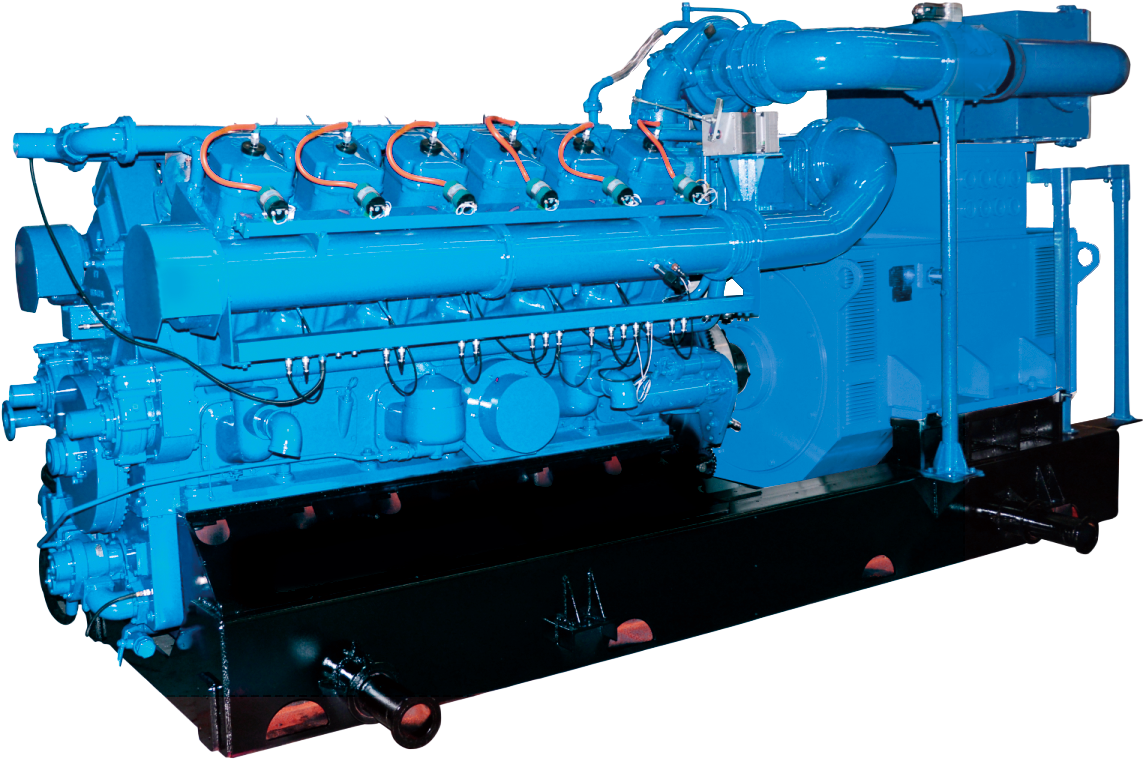

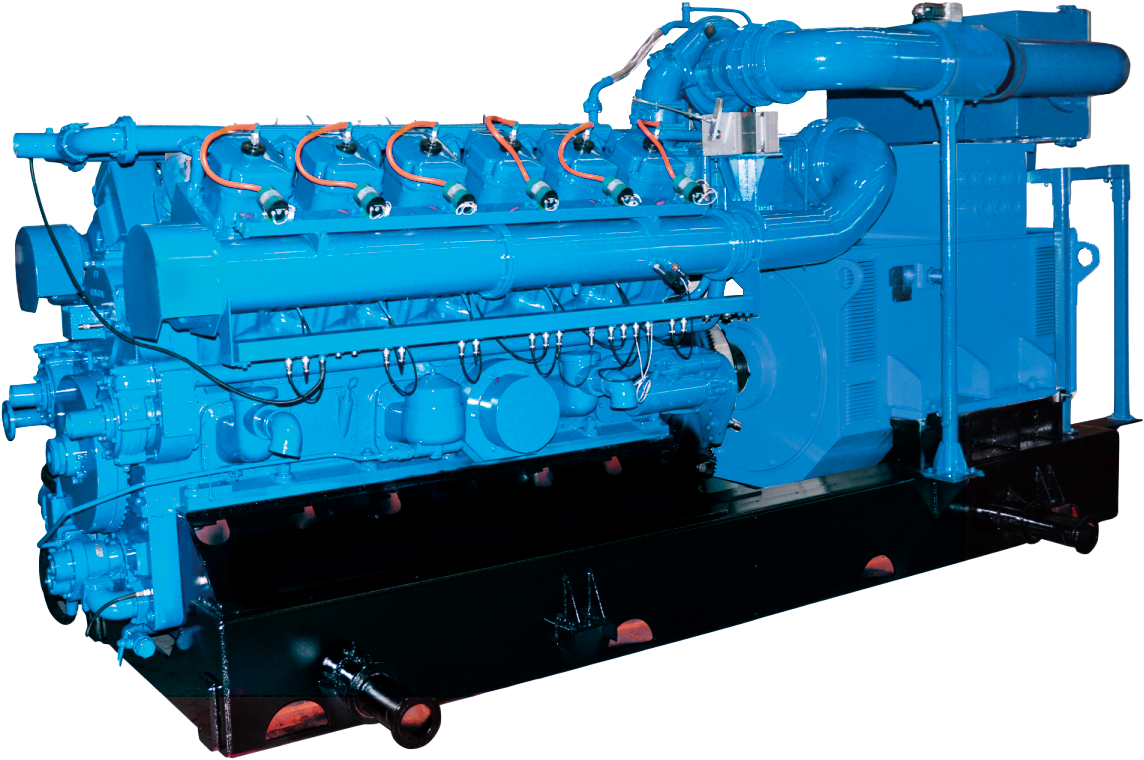

1. The crank connecting rod mechanism is the main moving component that completes energy conversion during the actual working cycle of the engine. It consists of a body assembly, a piston connecting rod assembly, and a crankshaft flywheel assembly. During the process of doing work, the piston undergoes linear motion in the cylinder under the pressure of gas, which is converted into the rotational motion of the crankshaft through the connecting rod, and outputs power from the crankshaft to the outside. During the intake, compression, and exhaust processes, the flywheel releases energy to convert the rotational motion of the crankshaft into linear motion of the piston.

2. The function of the valve mechanism is to regularly open and close the intake and exhaust valves according to the working sequence and process of the engine, allowing the combustible mixture or air to enter the cylinder and exhaust the exhaust gas from the cylinder, achieving the gas exchange process. The majority of valve trains use overhead valve trains, which are generally composed of valve sets, valve transmission sets, and valve drive sets.

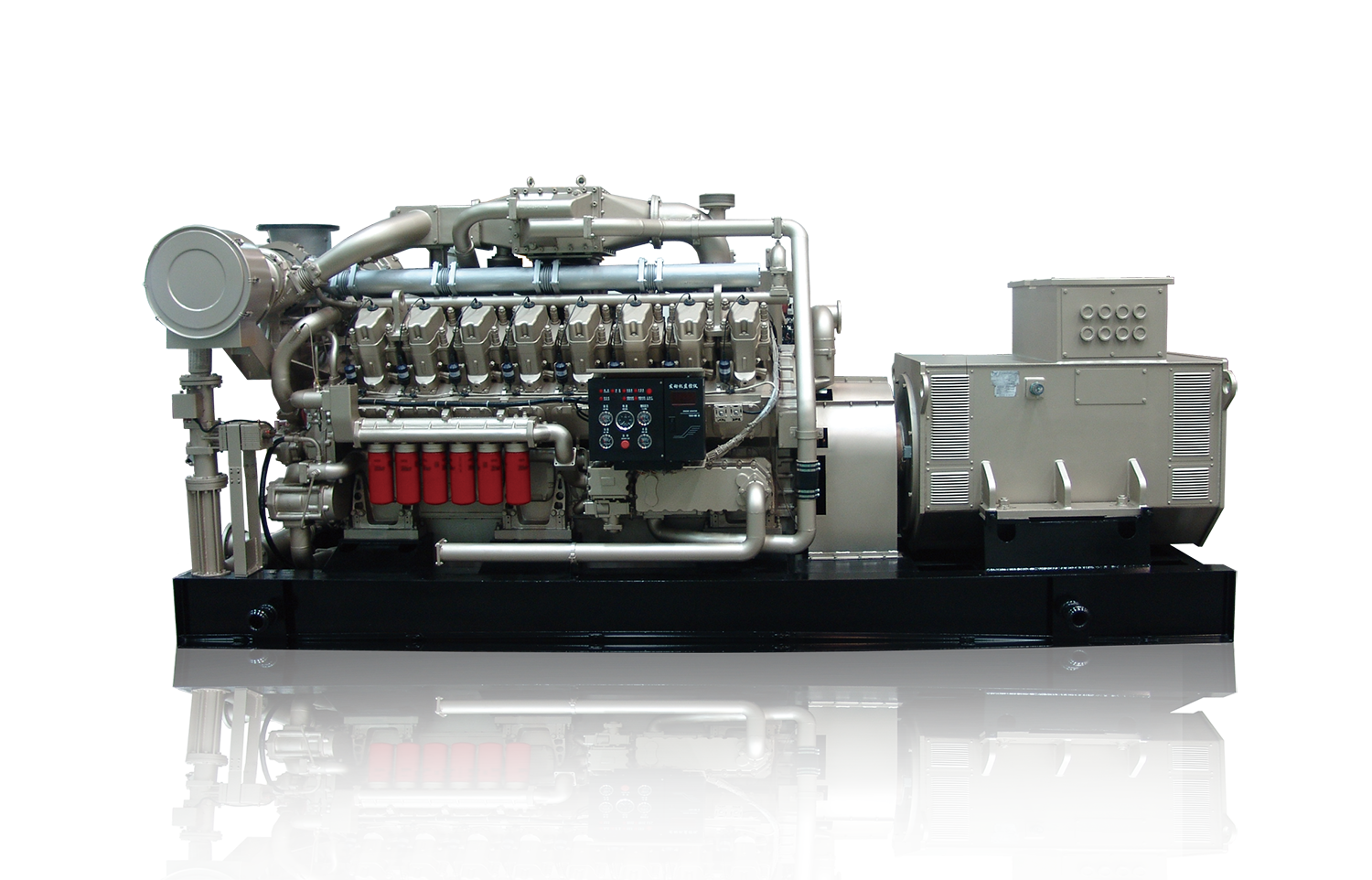

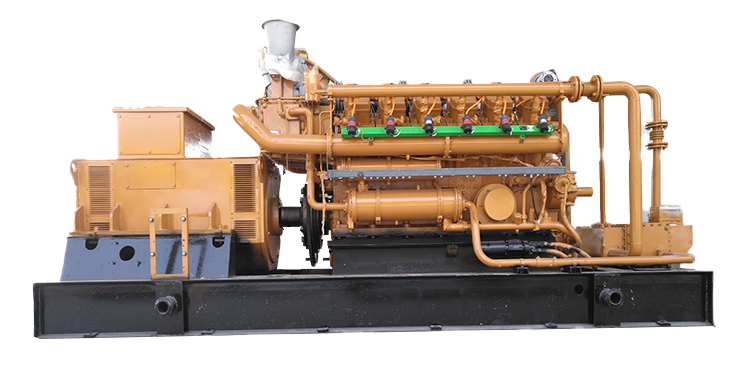

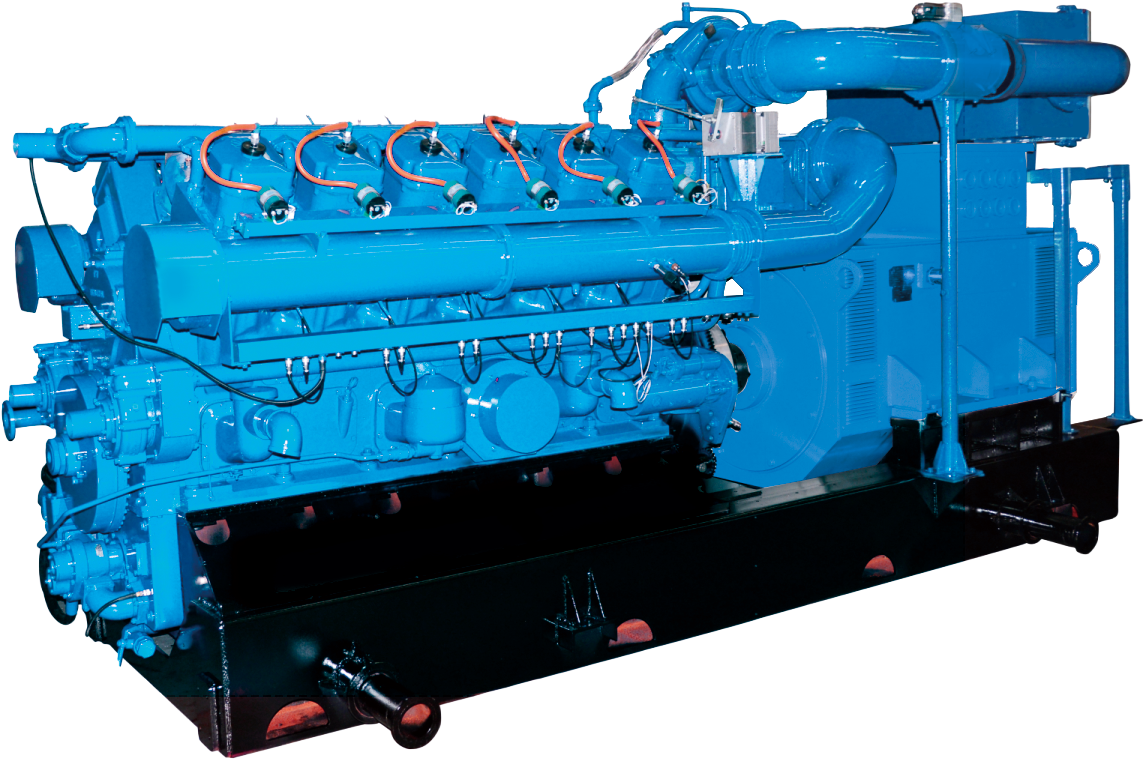

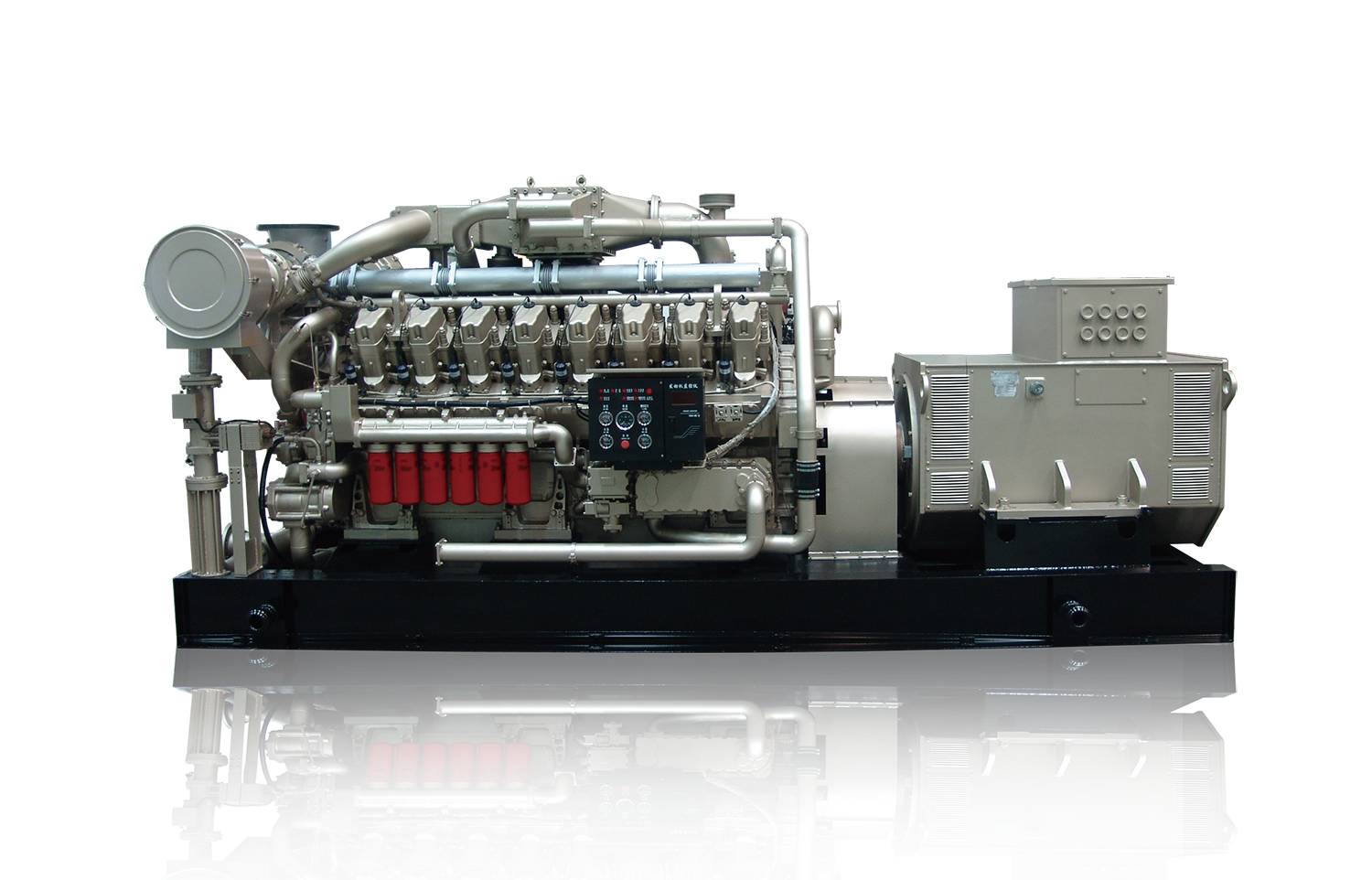

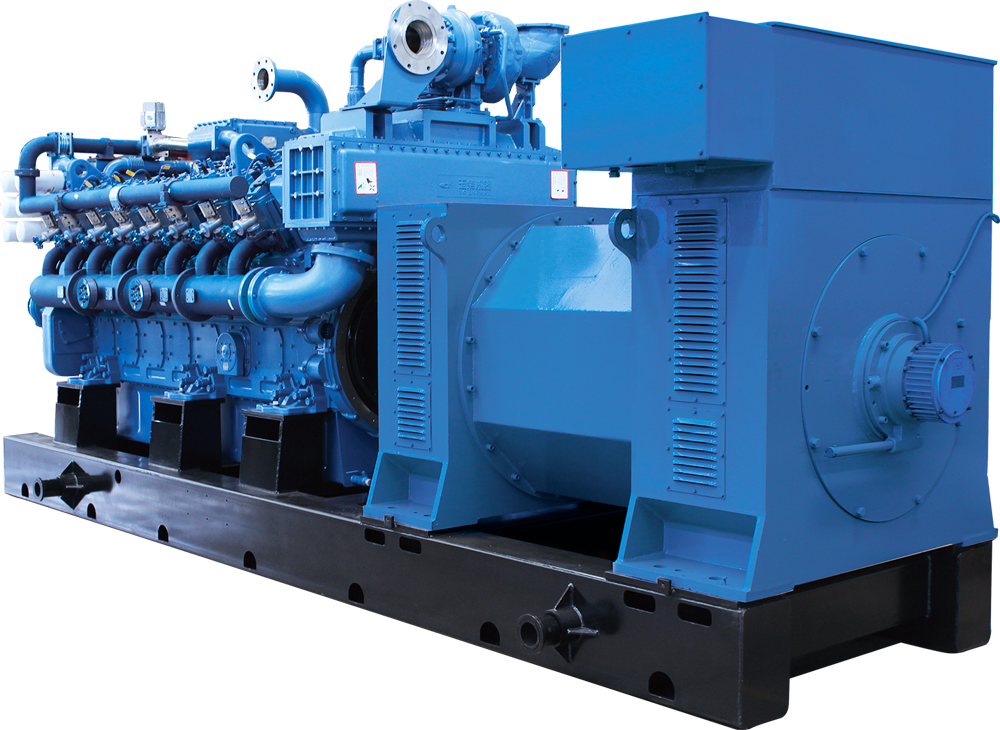

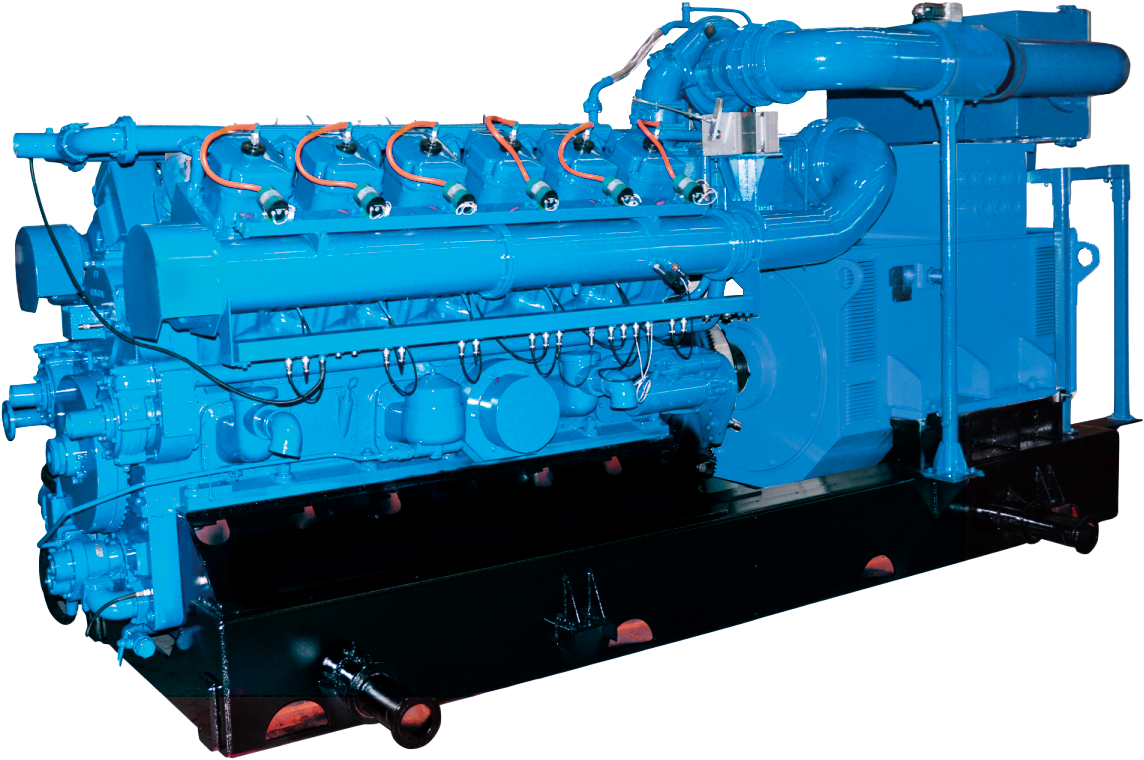

3. The function of the fuel supply system for gasoline engines is to prepare a certain amount and concentration of mixed gas according to the requirements of the engine, supply it to the cylinder, and exhaust the burnt exhaust gas from the cylinder to the atmosphere. The function of the diesel engine fuel supply system is to supply diesel and air separately to the cylinder, form a mixed gas in the combustion chamber and burn it, and finally exhaust the burnt exhaust gas. Biogas generator

4. Lubrication system The function of the lubrication system is to deliver a certain amount of clean lubricating oil to the surface of parts in relative motion to achieve liquid friction, reduce friction resistance, reduce wear of parts, and clean and cool the surface of parts. The lubrication system is usually composed of lubricating oil passages, oil pumps, oil filter and some valves.

5. The function of the cooling system is to timely dissipate some of the heat absorbed by the heated parts, ensuring that the engine operates at the most suitable temperature state. The cooling system of a water-cooled engine usually consists of a cooling water jacket, water pump, fan, water tank, thermostat, etc.

6. The ignition system refers to all equipment that can generate electric sparks between the spark plug electrodes on time. In a gasoline engine, the combustible mixture in the cylinder is ignited by an electric spark. Therefore, a spark plug is installed on the cylinder head of the gasoline engine, and the spark plug head penetrates into the combustion chamber. The ignition system usually consists of a battery, generator, distributor, ignition coil, and spark plug.

7. The starting system engine transitions from a stationary state to a working state. It must first use external force to rotate the engine's crankshaft, causing the piston to move back and forth. The combustible mixture in the cylinder burns and expands to do work, pushing the piston downward to rotate the crankshaft. Only then can the engine run on its own and the working cycle proceed automatically. Therefore, the entire process of the crankshaft starting to rotate under external force until the engine starts to automatically idle is called engine starting. The device required to complete the starting process is called the starting system of the engine. The gasoline engine is composed of the above two major mechanisms and five major systems, namely the crank linkage mechanism, valve distribution mechanism, combustion supply system, lubrication system, cooling system, ignition system, and starting system;

This article comes from: Gas Booster Pump. For more information, please click on: We will provide a satisfactory service for the questions you ask. Welcome to call us!

Tel:0531-69953988

Tel:0531-69953988  Add:101, Building 5, Liandong U Valley Science and Technology Innovation Center, Zhangjin Comprehensive Bonded Zone, No. 33688 Jingshi East Road, Suncun Street, Jinan Area, China (Shandong) Pilot Free Trade Zone

Add:101, Building 5, Liandong U Valley Science and Technology Innovation Center, Zhangjin Comprehensive Bonded Zone, No. 33688 Jingshi East Road, Suncun Street, Jinan Area, China (Shandong) Pilot Free Trade Zone