Biomass power generation is a type of renewable energy generation that utilizes the biomass energy possessed by biomass. It includes direct combustion of agricultural and forestry waste for power generation, gasification of agricultural and forestry waste for power generation, waste incineration for power generation, landfill gas for power generation, and biogas for power generation.

Biomass power generation includes direct combustion of agricultural and forestry waste for power generation, gasification of agricultural and forestry waste for power generation, waste incineration for power generation, landfill gas for power generation, biogas for power generation, etc.

1. Principle of direct combustion of agricultural and forestry waste for power generation

Direct combustion power generation refers to the direct combustion of biomass in a boiler to produce steam and drive a steam turbine and generator to generate electricity. The key technologies for biomass direct combustion power generation include biomass raw material pretreatment, boiler anti-corrosion, boiler raw material applicability and fuel efficiency, steam turbine efficiency, and other technologies.

When burning straw for power generation, there are various ways for straw to be fed into the furnace: straw can be packaged, crushed into granules (crushed), or crushed into powder, or mixed with coal and finally fed into the boiler. The production process is to process biomass such as straw into a form suitable for boiler combustion (powder or block), and send it into the boiler for full combustion, converting the chemical energy stored in biomass fuel into thermal energy; The heat in the boiler generates saturated steam, which is further heated into superheated steam in the superheater and enters the turbine, driving the turbine generator unit to rotate, converting the internal energy of the steam into mechanical energy. Finally, the generator converts the mechanical energy into electrical energy.

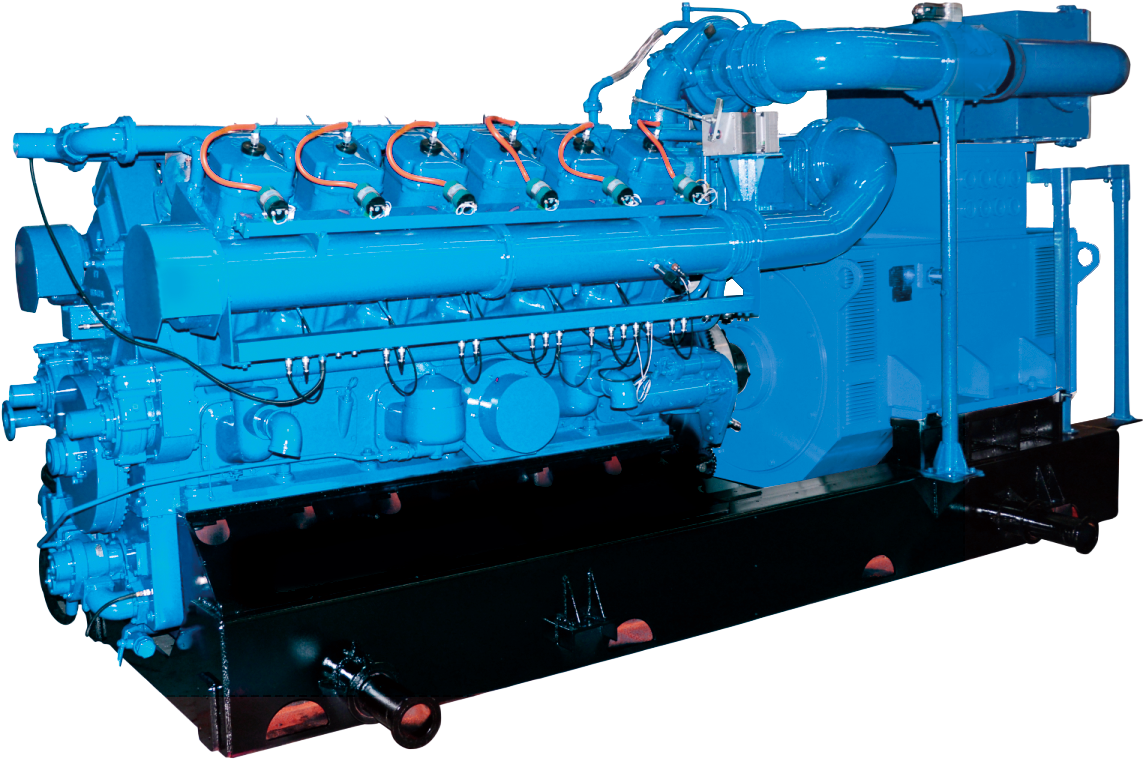

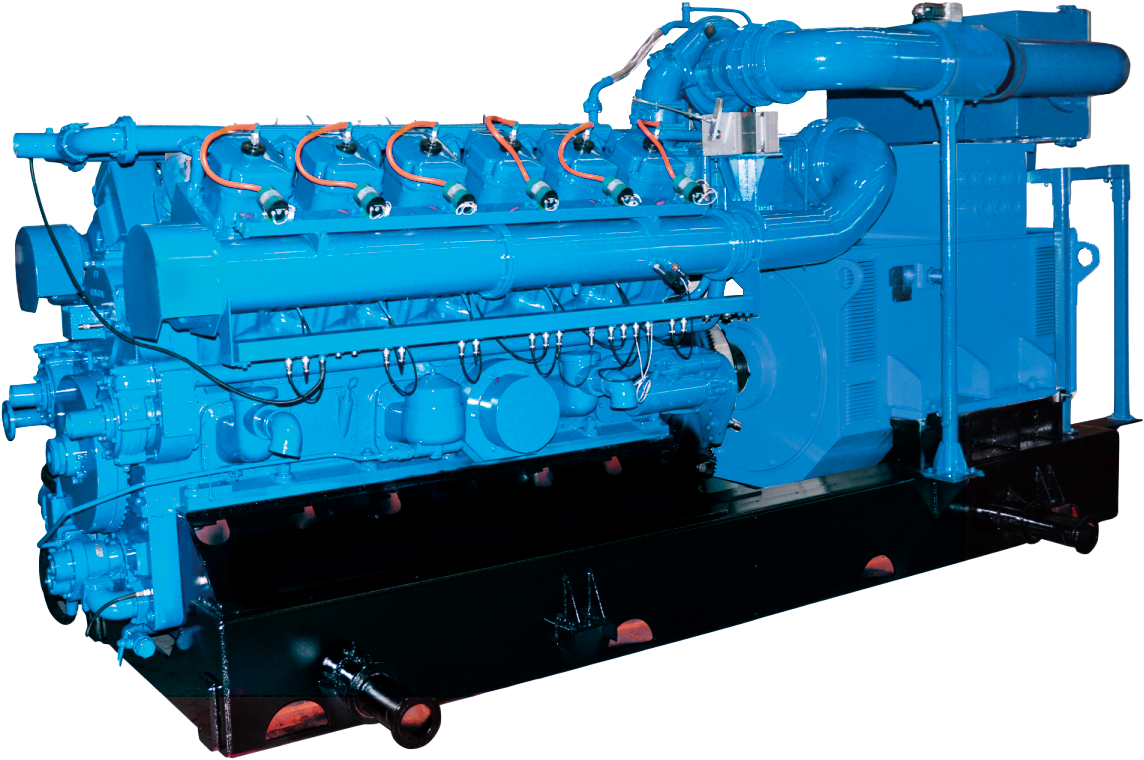

2. Principles of biomass gasification for power generation

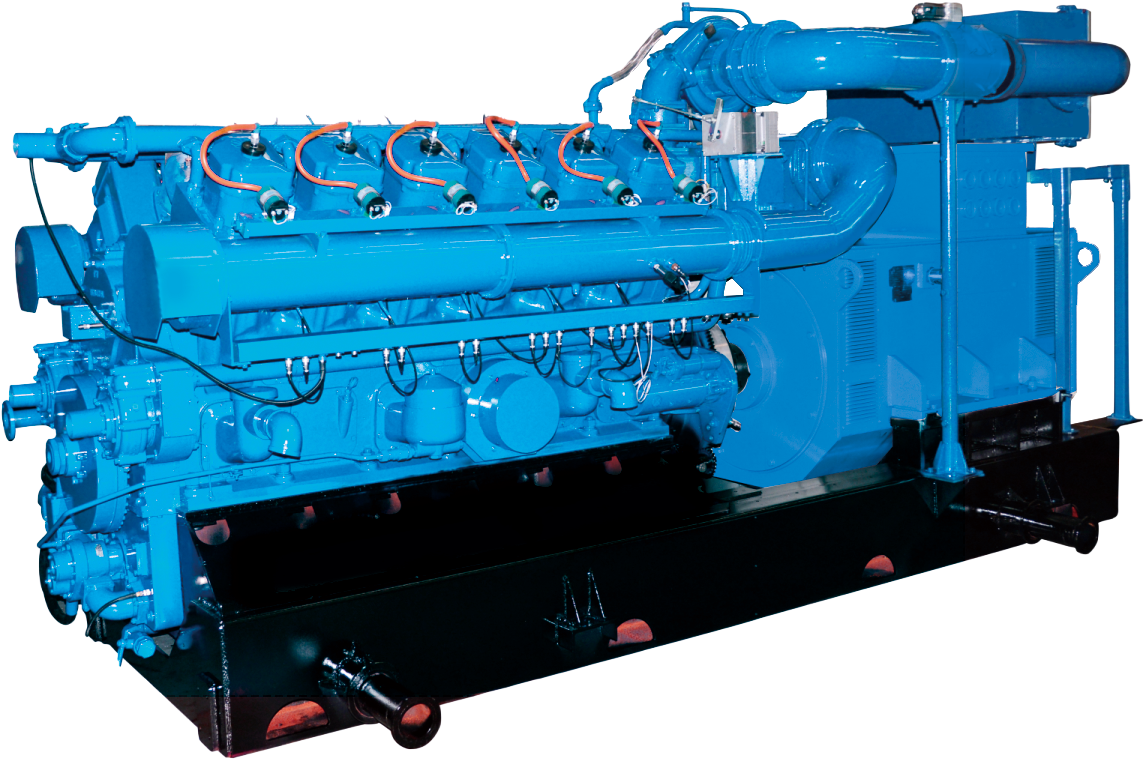

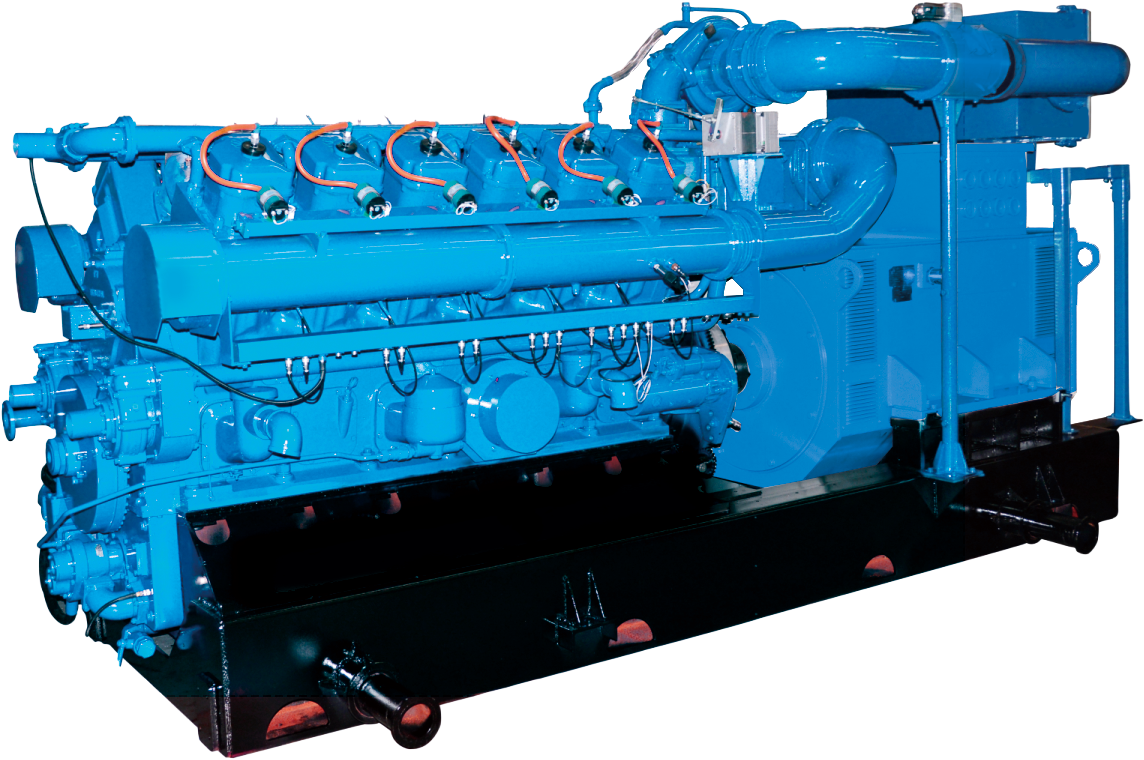

Biomass gasification power generation technology refers to the conversion of biomass into gas fuel in a gasifier, which is purified and directly burned in a gas engine for power generation or directly fed into a fuel cell for power generation. One of the key technologies for gasification power generation is gas purification. The gasified gas contains certain impurities, including ash, coke, and tar, which need to be removed through a purification system to ensure the normal operation of the power generation equipment.

The basic principle of biomass gasification power generation technology is to convert biomass into combustible gas, and then use combustible gas to drive gas power generation equipment for power generation. It can not only solve the shortcomings of biomass being difficult to burn and distributed dispersedly, but also fully utilize the advantages of compact equipment and low pollution of gas power generation technology. Therefore, gasification power generation is one of the most effective and clean utilization methods of biomass energy.

The gasification power generation process mainly includes three aspects: firstly, biomass gasification, which converts solid biomass into gas fuel in a gasifier; The second is gas purification. The gasified gas contains certain impurities, including ash, coke, and tar, which need to be removed through a purification system to ensure the normal operation of gas power generation equipment; The third is gas power generation, which utilizes gas turbines or gas internal combustion engines for power generation. In some processes, in order to improve power generation efficiency, waste heat boilers and steam turbines can be added to the power generation process.

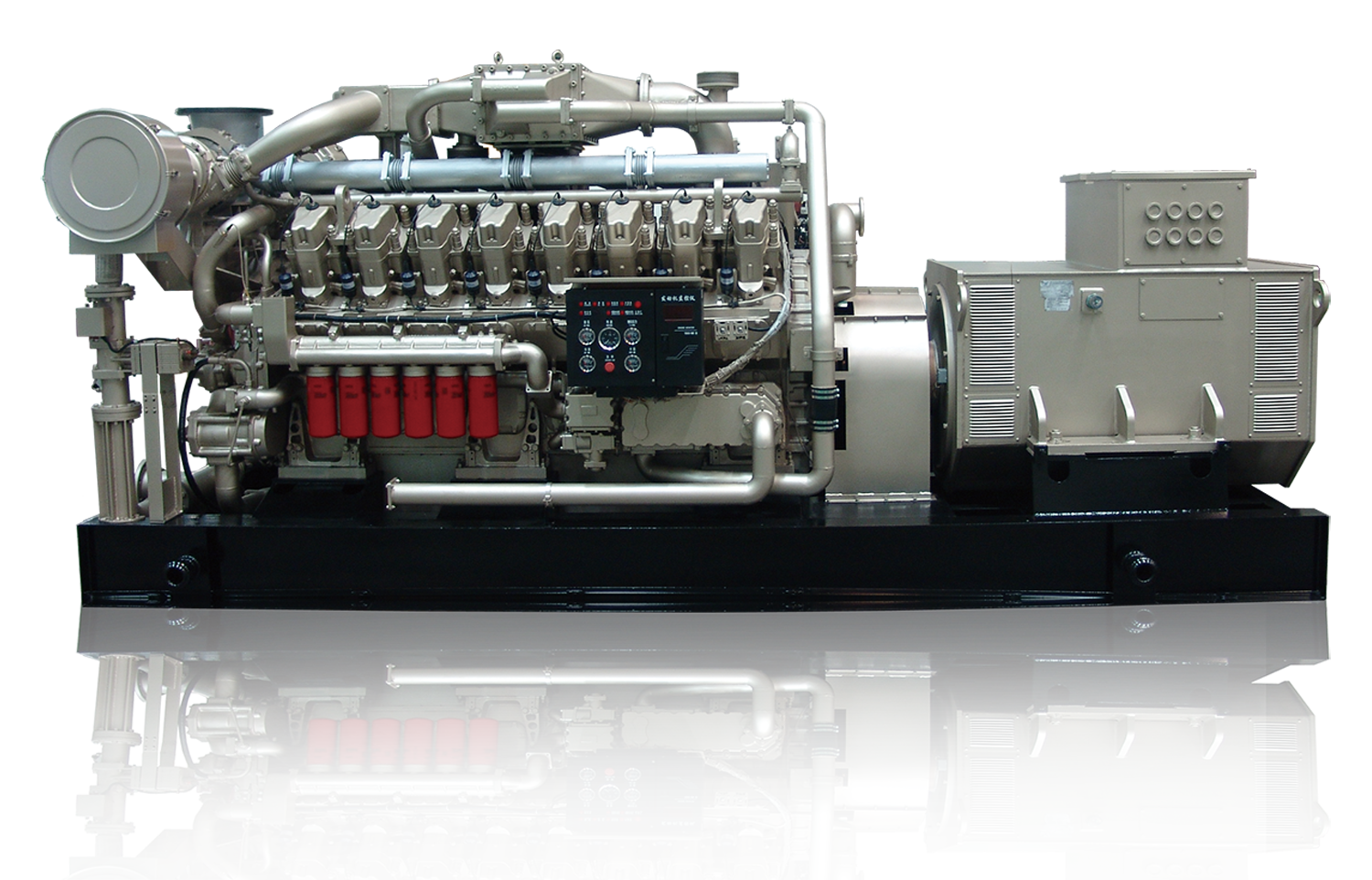

3. Principles of biogas power generation

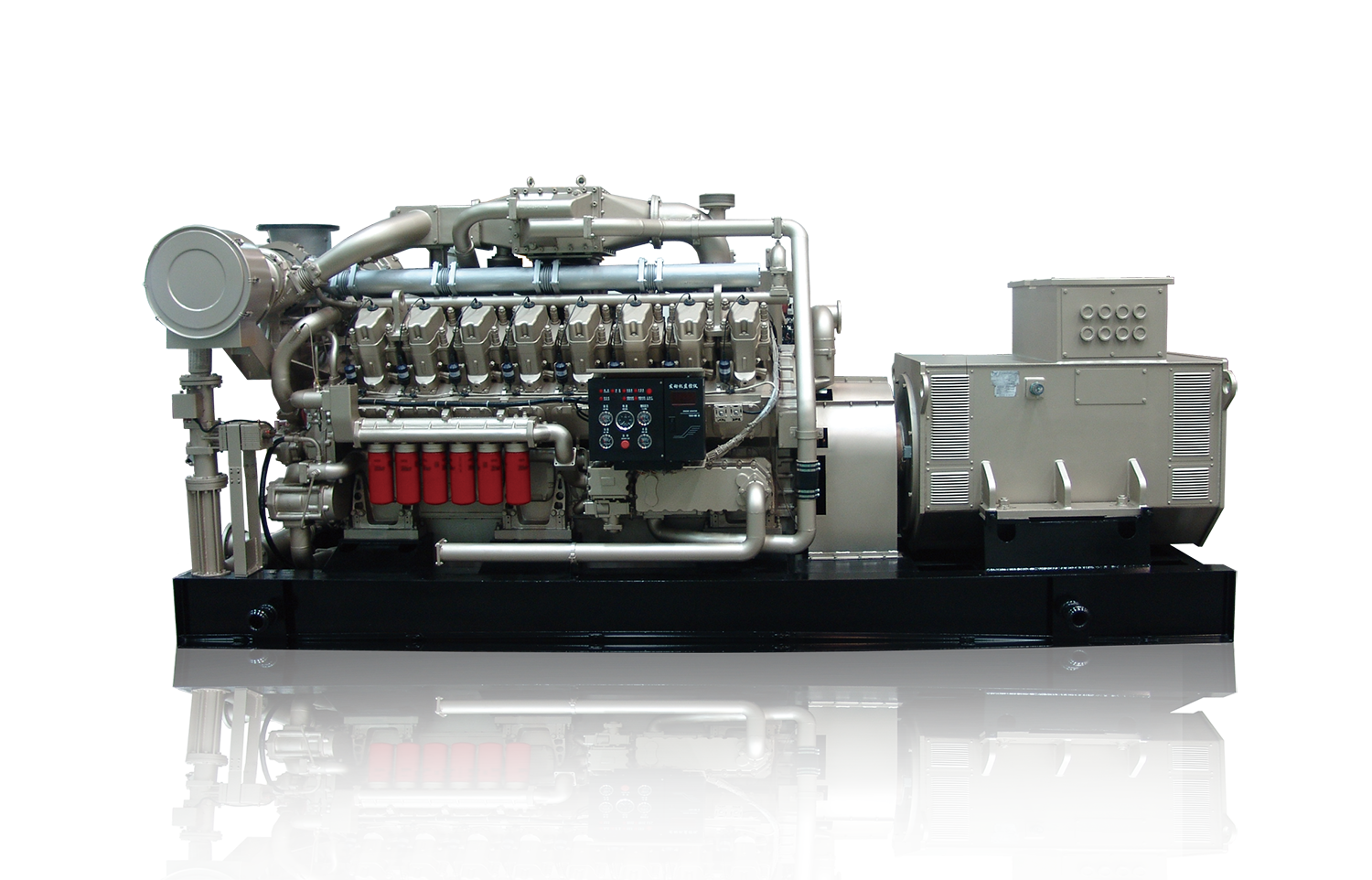

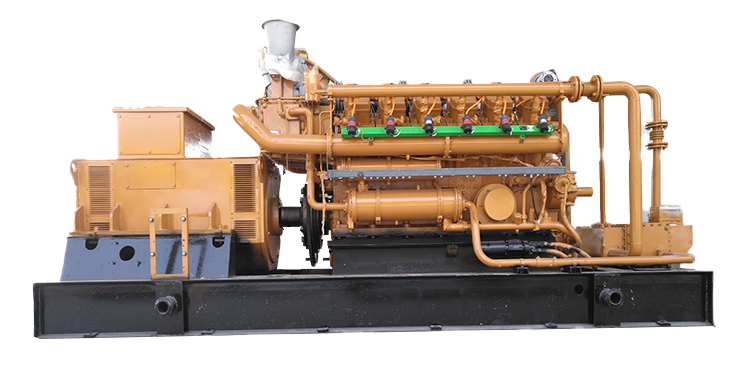

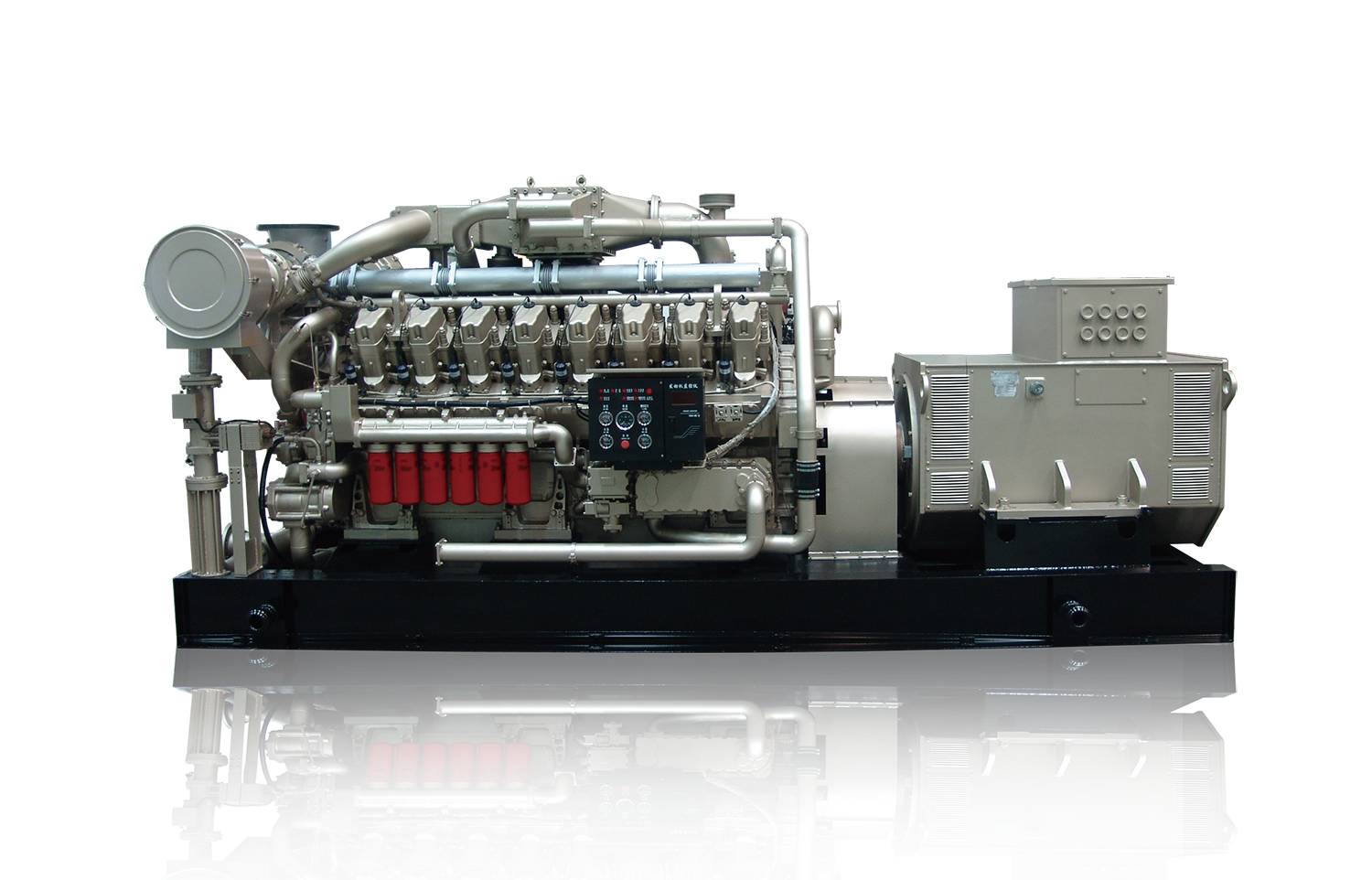

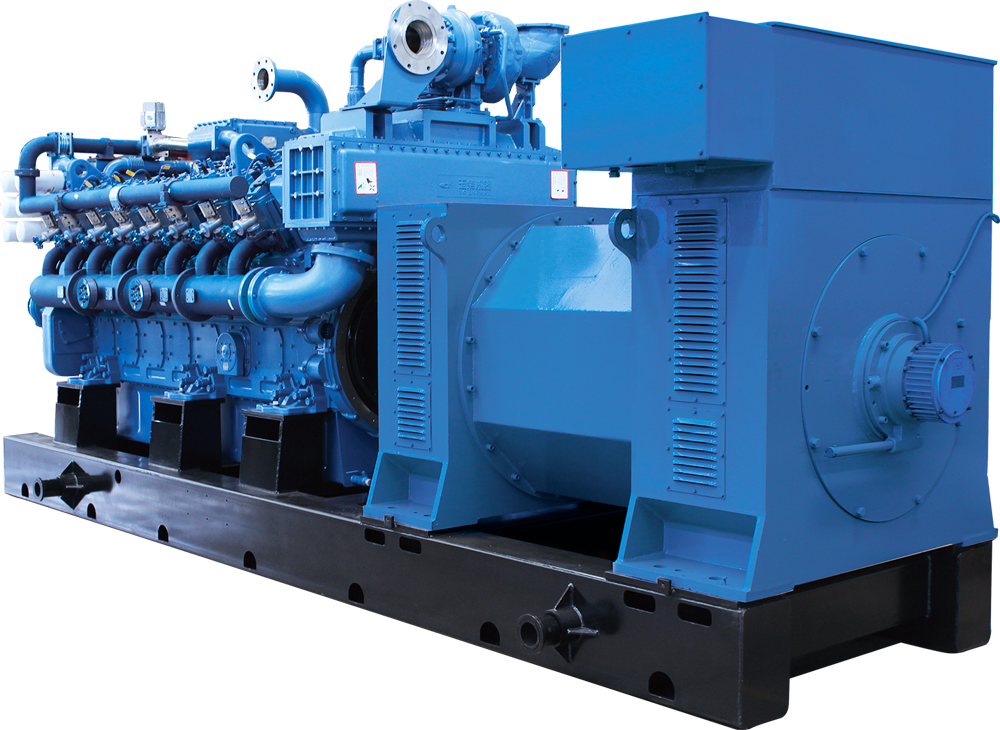

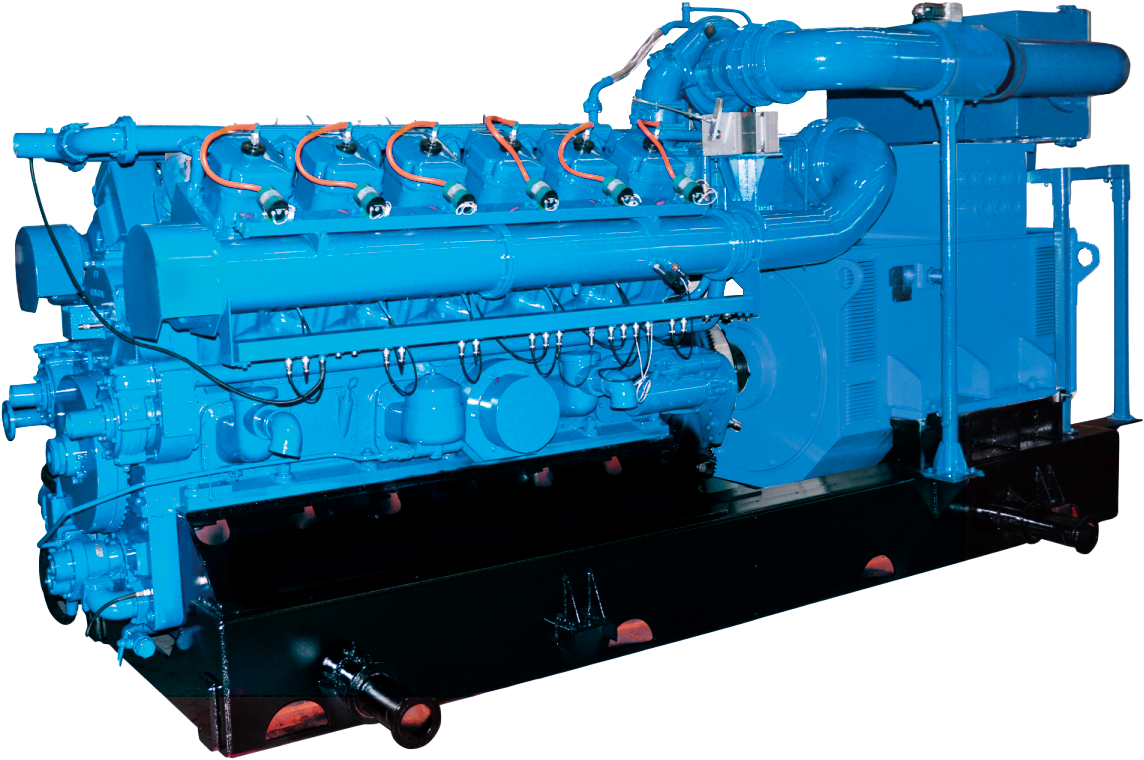

The main principle of biogas power generation is to use a large amount of organic waste in industry, agriculture, or urban life to drive the power generation unit with biogas generated through anaerobic fermentation treatment. The equipment used for biogas power generation is mainly internal combustion engines, which are generally modified from diesel or natural gas units.

The biogas power generation system uses a closed thermal power unit (BTTPU), which includes a biogas engine, generator, and a heat exchanger with heat output. The main difference from current liquid fermentation is that the organic matter of the material does not require a liquefaction process. In a high-temperature anaerobic environment, the biomass raw material is directly loaded into a modular sealed fermentation equipment. Under the circulation of the leachate, the dry material is moist, and after a few weeks, it becomes high-quality biogas with a methane content of 70% to 80%. It is converted into electricity through a biogas engine and waste heat is utilized.

4. Waste incineration power generation

Garbage incineration power generation includes garbage incineration power generation and garbage gasification power generation. It not only solves the problem of garbage treatment, but also recycles and utilizes the energy in garbage, saving resources. Garbage incineration power generation uses the heat released by garbage burning in the incineration boiler to heat water to obtain superheated steam, which drives the steam turbine to drive the generator to generate electricity. Waste incineration technology mainly includes layered combustion technology, fluidized bed combustion technology, rotary combustion technology, etc. The developed gasification and melting incineration technology includes two processes: gasification of waste at temperatures ranging from 450 ° to 640 ° C and melting combustion of carbon containing ash above 1300 ° C. The waste is thoroughly treated, the process is clean, and some resources can be recovered, making it the most promising waste power generation technology.

5. Landfill gas power generation

During the process of landfilling, due to the lack of oxygen inside the landfill, the organic matter in the waste will ferment and produce a large amount of biogas (landfill gas). On average, each ton of waste can produce about 100-200 cubic meters of landfill gas during the lifespan of the landfill, which is mainly composed of methane, carbon dioxide, hydrogen sulfide, nitrogen, and other gases.

Landfill gas power generation adopts a complete concept of garbage and biogas collection and utilization. Through advanced garbage and biogas collection systems, transportation systems, biogas purification systems, and biogas power generation systems, garbage and biogas are fully utilized to generate electricity, which is integrated into the urban power grid and provides clean energy to electricity users. Therefore, at present, landfill gas power generation is a harmless treatment method that can effectively utilize waste gas resources for power generation while reducing air pollution. It is a project that conforms to the national goal of "energy conservation and emission reduction" and is a typical "low-carbon economy".

Tel:0531-69953988

Tel:0531-69953988  Add:101, Building 5, Liandong U Valley Science and Technology Innovation Center, Zhangjin Comprehensive Bonded Zone, No. 33688 Jingshi East Road, Suncun Street, Jinan Area, China (Shandong) Pilot Free Trade Zone

Add:101, Building 5, Liandong U Valley Science and Technology Innovation Center, Zhangjin Comprehensive Bonded Zone, No. 33688 Jingshi East Road, Suncun Street, Jinan Area, China (Shandong) Pilot Free Trade Zone